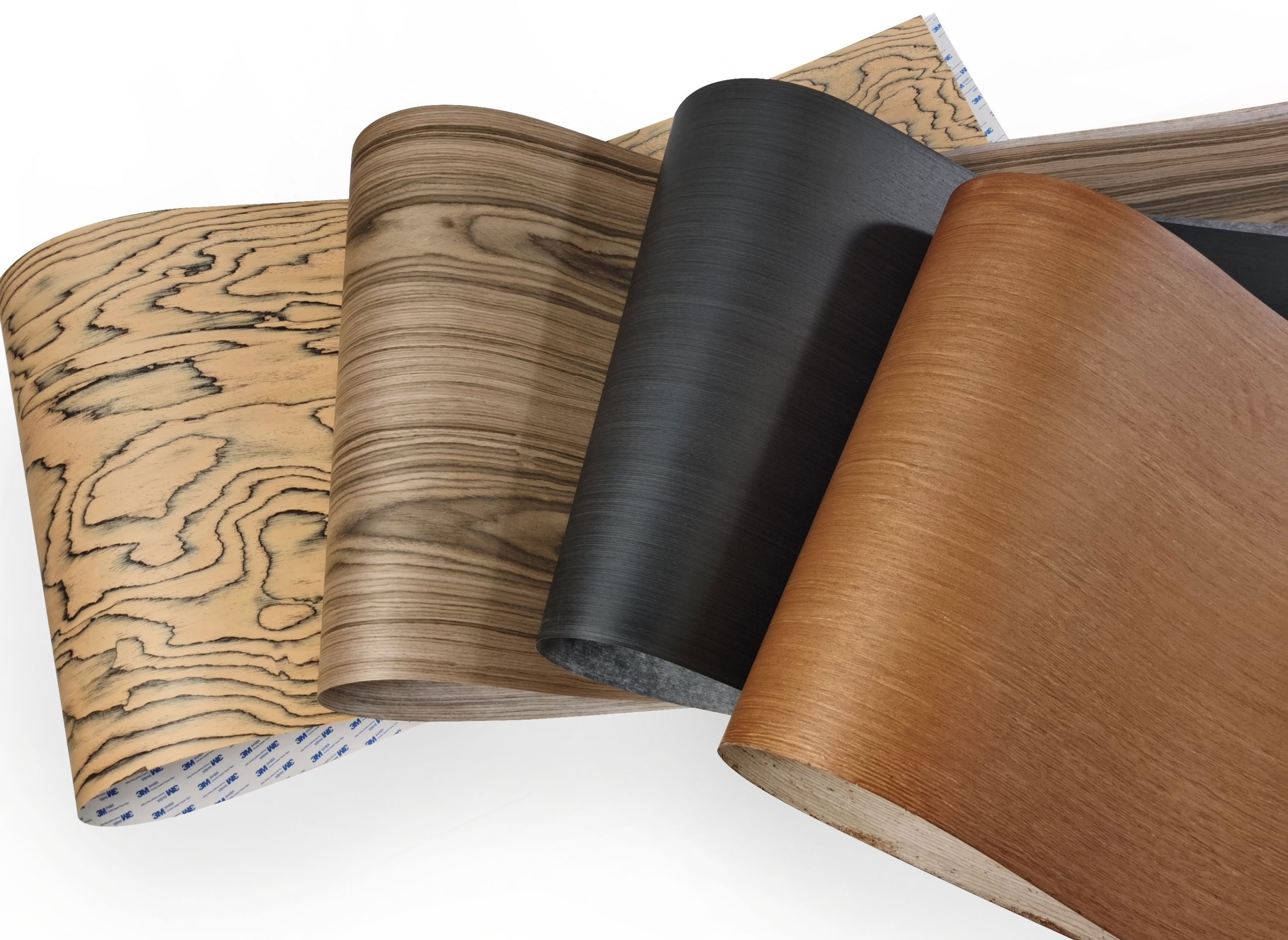

Engineered Wood Veneer:

The Secret Behind Stunning Musical Instruments

When we think of engineered wood veneer, furniture and interiors often come to mind—but this remarkable material also plays a vital role in crafting some of the world’s finest musical instruments. From the warm resonance of acoustic guitars to the sleek aesthetics of high-end pianos and percussion, veneer is the unsung hero of musical craftsmanship. If you’ve ever wondered why certain instruments look and sound so exquisite, the answer often lies in the artful use of wood veneer.

Why Veneer is a Musician’s Best Friend

Unlike solid wood, engineered veneer offers consistent quality, stability, and stunning visuals—all critical factors in instrument making. Here’s why luthiers, drum makers, and piano builders rely on it:

Tonal Consistency – Veneer eliminates natural imperfections that can affect sound, ensuring uniform resonance.

Lightweight Strength – Thin layers reduce weight without sacrificing durability (key for travel-friendly instruments).

Aesthetic Perfection – Flawless grain matching creates visually striking instruments.

Sustainable Choice – Maximizes rare tonewoods while minimizing waste.

Veneer in Iconic Instruments

Acoustic Guitars: Where Beauty Meets Sound

High-end acoustic guitars often feature veneered tops, backs, and sides—especially when using rare or exotic woods like:

Koa – Hawaiian treasure with a balanced, bright tone.

Cocobolo – Deep, rich overtones with fiery grain patterns.

Maple Burl – Stunning figuring for custom boutique guitars

Did you know? Many “solid wood” guitars actually use veneer overlays on headstocks and bindings for intricate inlay work.

Pianos & Keyboards: Elegance in Every Grain

From grand pianos to synthesizers, veneer provides:

Seamless Cabinet Finishes –

Durability Against Humidity –

Custom Designs –

Drums & Percussion:

Warmth & Projection

Drum shells benefit from veneer in surprising ways:

Layered Construction

Exotic Finishes

Hybrid Shells

Unique Instruments

From Violins to Beatbox Skins

Violins & Cellos –

Handpans & Steel Tongue Drums –